High Performance Powder Coatings

How And Why Are Powder Coatings So Resistant.

Powder coatings have been a growing part of the industrial coatings market for more than 50 years and today represent approximately 15-20% of the global consumption for industrial coatings. Over the last fifteen years or so powder coatings have found market penetration in high performance applications even further expanding its use and viability. There are four primary areas of high performance that have continued to improve and make powder a good alternative to traditional liquid paint for high-performance applications. They include ultraviolet (UV) resistance, chemical resistance, corrosion resistance and heat resistance.

Sunlight Resistance

Color and gloss retention is always a concern for coatings when exposed to the harsh UV rays of the sun and powder coatings are no exception. Today there are many options to select from that now include powder coatings for one year exposure, five year exposure and even ten year exposure to sunlight with great retention results.

Powder coatings can be formulated for standard durable products, super durable products and flouro-polymer powder coatings for very long-term outdoor UV resistance.

A standard polyester can provide good color and gloss retention for one to five years depending on the specific color and pigments in use. Standard specifications that call for good UV resistance can be met with a high-quality polyester powder coating.

Specifications that call for a more durable finish from five to 10 years can be met with a super-durable powder coating. The resin system for these coatings is able to withstand sunlight and deliver better resistance over time. The product must have the right pigments and be engineered to take advantage of the super-durable resin system. Some of the more neutral colors are excellent targets for these exceptional products but some colors may be harder to formulate for this type of performance.

For installations that such as building monumental aluminum the super-durable powder may not always satisfy the architectural standard needed. In these cases the specification can be met with a fluoro-polymer powder that can provide sunlight resistance with minimal gloss and color loss for over ten years. FEVE and PVDF powders contain infrared reflective pigments that provide UV resistance for a longer period of time in the harshest environment.

Chemical Resistance

Chemical resistance is also an area of concern in many different market spaces. Historically epoxy powder coatings were the only option and were susceptible to seeds and application issues. Today not only have there been many formulation advances for epoxy technology giving them a broader operating window but additional chemistries are now available that have shown exceptional chemical resistance. These coatings can meet harsh standards and many colors can be formulated in polyester chemistries.

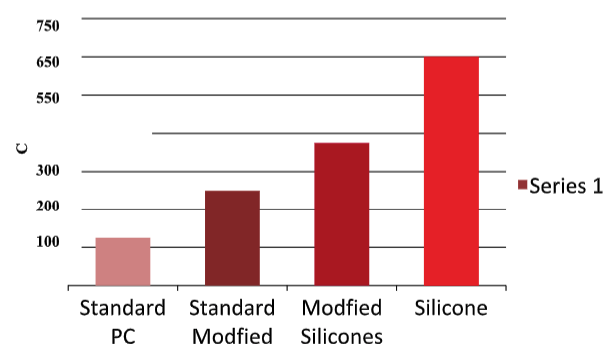

High-Heat Resistance

In many applications heat resistance is necessary and for powder coatings limitations in the higher temperatures have been problematic. Exposure to high-heat can cause an organic polymer to shrink and crack and may eventually cause delamination of the coating. In recent years new techniques have been developed allowing for higher operating temperature and even offering color choices in some heat sensitive applications.

Powder Formula

Corrosion Resistance

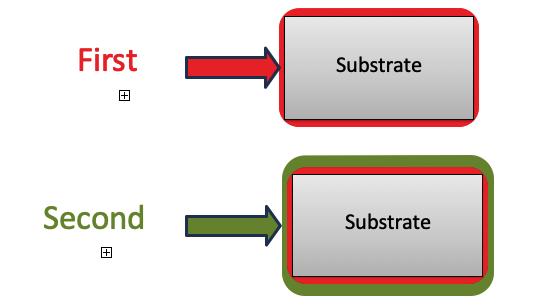

Corrosion protection has always been a very strong aspect of powder coatings but now with zinc containing powder coatings, fusion bond epoxy (FBE) powder coatings and using a dual layering process corrosion resistance has been dramatically improved and can be used in virtually any corrosive application environment.

The corrosion resistance is a function of the total process, not just the particular powder used. The fabrication of the part being coated has to avoid areas that cannot be coated or may trap water. The part has to have a proper cleaning and preparation process and the coating must be thick enough and not leave any voids or thin areas on edges or recesses.

Layers Provide Superior Edge Coverage

Powder coatings have long been recognized as the best alternative for environmental concerns. As time has passed and more products have come on the market powder coating has also established a market for the best possible performance element you may need.