Oven Cure Cycle

Expert Tips: How to Get Rid of All Gremlins and Use the Oven to the Full

Powder materials are formulated to react when exposed to thermal energy by melting into a film and then chemically cross-linking into a finished film. The performance and appearance of the powder film is dependent of the completion of minimum exposure time to a prescribed substrate temperature.

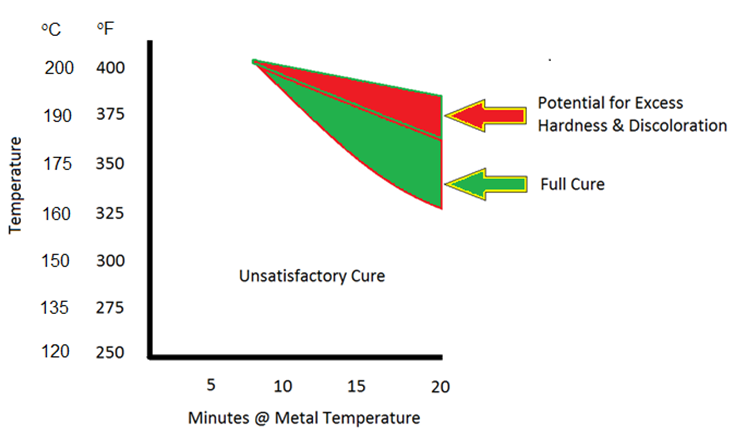

There is some flexibility in the exact time and temperature that can be expressed in curve with a vertical axis of temperature and horizontal axis if time. There is a minimum temperature that must be reached in order to achieve cross-linking. The temperature can be higher within certain limits and the time can be somewhat shorter if the temperature is higher. This window of cure is expressed in the graph shown below. A combination of time and temperature in a convection oven that fits within the green area should reach full film properties.

The graph expresses the temperature needed by the substrate, not just the surrounding air around the part. Heavier parts will need a longer overall cycle to allow for time to elevate the part temperature. More mass will require more time in the oven.

The short oven story is so often told that it seems like a gremlin lives in our industry and routinely interferes with good oven design. In addition, many companies exceed the original design line speed of their oven and reduce the dwell time in the process.

There are ways to reduce the overall time in the oven. One method that is used is application of thermal energy with infrared (IR) emitters as the total cure or part of the cure cycle. IR can provide a significant additional amount of cure in a relatively small space because the electromagnetic energy heats the part surface rapidly and starts cross-linking much faster than standard convection heating.

IR should always be tested to confirm that it works well for the variety of parts that need to be processed. IR is fast because it is much more intense and transfers heat rapidly. A part with a broad surface and very little mass will heat up very quickly so care must be taken to avoid excess exposure to the radiant energy. A part with limited surface exposed to the emitter but a thick mass will heat much slower and the energy may not effectively reach an area that is not directly exposed to the emitter. Proper testing can show how much benefit it can provide and how the various masses and shapes will perform in the IR oven. Flatter parts with less geometry are better candidates for a lot of IR while more complex shapes without a lot of exposed surface may be less receptive to IR.

Powder cure times can be accelerated in some cases when the oven is too short. Shorter cure or lower temperature cure can sometimes be achieved by adjustment of the formula with a catalyst. Faster cure powders may cost more and a low-temperature cure product may be less stable in storage. In some situations that may be the only way to get the needed cure.

Addition of IR can be useful for some operations. Powder can be formulated for lower temperature or faster cure cycles. Making the oven big enough to begin with is the best solution.